Robotic Automation Systems

Robotic Automation Systems are a lean manufacturing solution that minimizes your production lines' dependence on human labor. They assist in various manufacturing tasks and can even handle entire processes on their own. Being reprogrammable, they offer flexibility and can be easily integrated with future production changes. By investing in a robot automation system, you can increase productivity, enhance product quality, boost production capacity, and easily scale up your production volumes. With Robotic Automation Systems, you can effortlessly perform tasks such as palletizing, packaging, machine feeding, cutting, and welding applications.

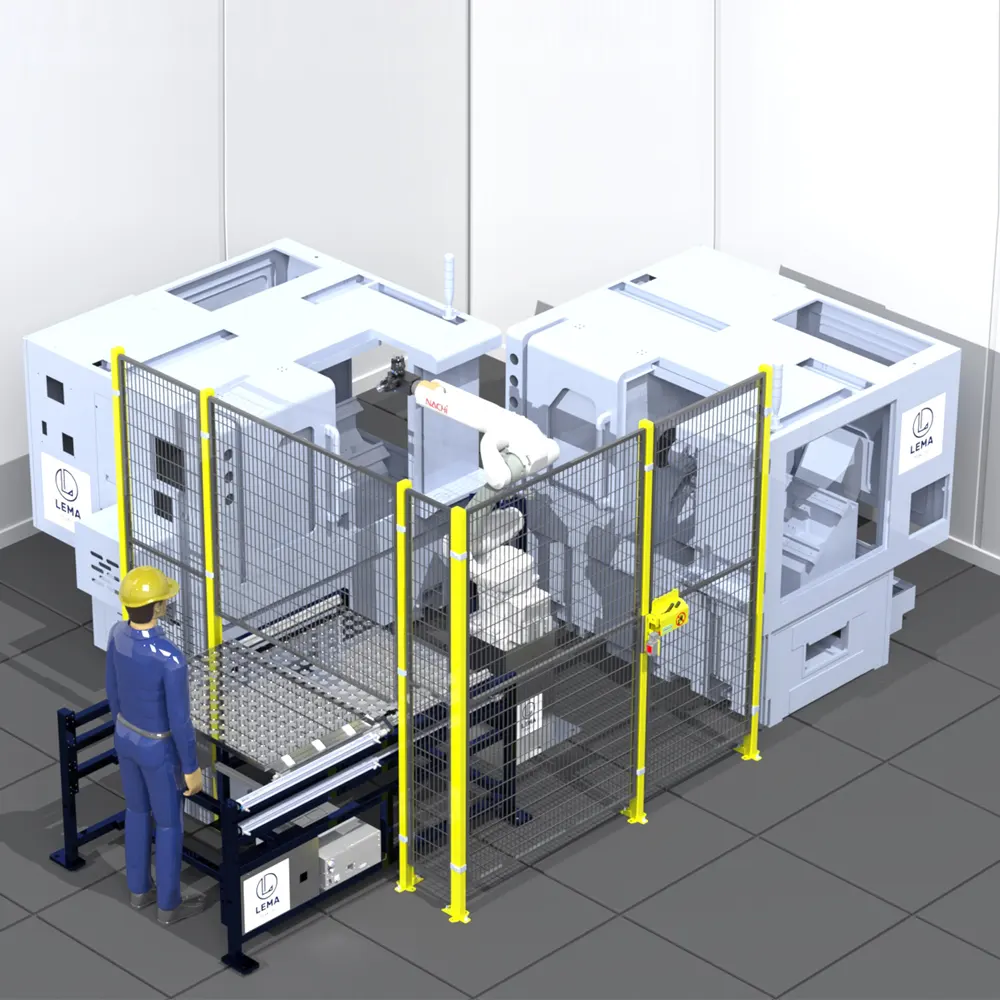

CNC MACHINE FEEDING

CNC Machine feeding, with Robotic Automation Systems, is one of the most commonly used fundamental applications. It mainly consists of a robot, robot robot gripper and product fixture. The selection and design of all these components depending on the structural characteristics of the product to be fed, your line capacity, and the processing method. When choosing a robot, the positions of the workstations and the weight of the product are taken into account. If your production volume is high, you can assign one robot to each workstation, or for low-volume productions, one robot can be used for multiple workstations. In cases where more than three workstations need to be fed, a Robot Slider can also be used. Finger design is made according to the structure of your product. The number of holders in the robot gripper is determined based on your production capacity. As a product fixture, drawer fixture, conveyor, or camera application can be used.

Reliable Robot Technology

Uninterrupted ProductionPowerful Automation

Maximum Line Efficiency

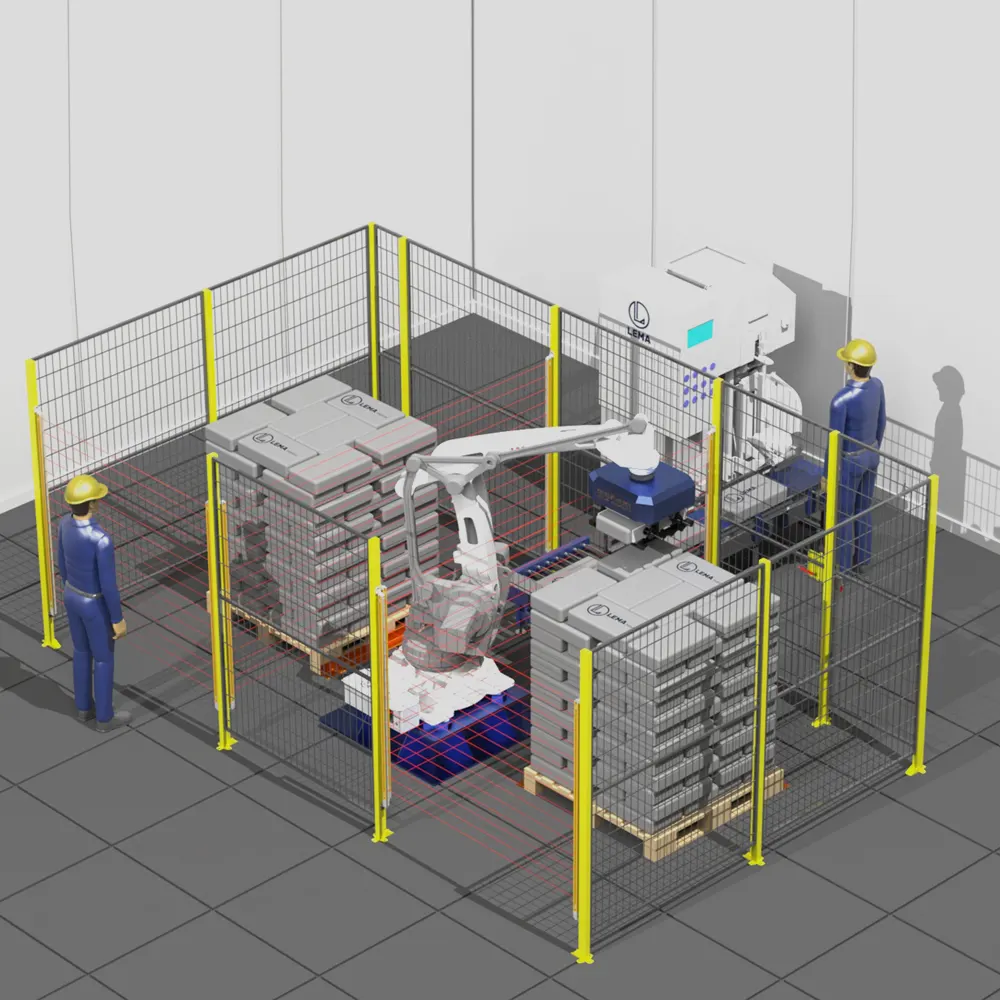

BAG PALLETIZING

Palletizing of bags using Robotic Automation Systems is another widely used application. It primarily consists of a robot and a robotic gripper. The selection and design of all these components depending on the structural characteristics of the product to be palletized and your line capacity. When choosing a robot, the pattern and product weight are taken into account. If your production volume is high, you can assign one robot to each filling line, or for low-volume productions, you can direct multiple production lines to one robot through conveyor transfer systems and palletize onto different pallets if desired. We can smoothly perform palletizing with our specialized robotic bag gripper. Palletizing can be done directly onto the pallet or arranged on a conveyor and taken out of the system. Additionally, an automatic pallet feeding machine can be easily integrated into the system if required.

Automated Pallet Management

High-Speed PalletizingReduced Labor Costs

Powerful Solutions for Heavy Loads

BOX PALLETIZING

Box palletizing is one of the another commonly used applications with Robotic Automation Systems. It primarily consists of a robot and a robotic gripper. The selection and design of all these components depending on the dimensions of the box, the box pattern, the number of separators, and your line capacity. When choosing a robot, the pattern and product weight are taken into account. If your production volume is high, you can assign one robot to each filling line, or for low-volume productions, you can direct multiple production lines to one robot through conveyor transfer systems and palletize to different pallets if desired. We can smoothly perform palletizing with our specialized robotic box hand. Palletizing can be done directly onto the pallet or arranged on a conveyor and taken out of the system. Additionally, an automatic pallet feeding machine can be easily integrated into the system if required.